A 1997 NIOSH analysis of a large number of miner audiograms, showed that by age 50, approximately 90% of coal miners and 49% of metal/non-metal miners had hearing impairment. In contrast, only 10% of the population that experienced non-occupational exposure to noise had any hearing loss by the age of 50 (Rider, 1999). Despite more than 30 years of regulation within the mining industry, 76% of miners are still exposed to hazardous levels of noise. This represents the highest prevalence rate of hazardous noise exposure in any work sector (Reinke, 2010).

Occupational hearing loss can be defined as hearing impairment of one or both ears, partial or complete, that results from a worker's employment job tasks. It includes both acoustic trauma and noise-induced hearing loss. Acoustic trauma is injury to the inner ear usually arising from a single or short-term exposure to intense noise (e.g., explosion). The damage is often related to a single incident. Noise-induced hearing loss, on the other hand, is cumulative damage to the inner ear over a period of months or years of exposure to hazardous noise (Fundamentals of Industrial Hygiene, 5th Ed, pp. 108).

Hearing loss is not the only hazard associated with noise in the mining industry. An additional problem with work environments exhibiting hazardous noise levels include impedance of audio cues of work processes and audio warning signals. This is especially crucial in mining where audio cues are imperative to safety.

Noise-Induced Hearing Loss

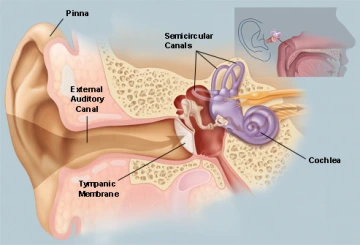

The ear is divided into three areas: The outer ear, the middle ear, and the inner ear.

- Outer Ear: The outer ear includes the exterior portions of the ear and the ear canal. This portion of the ear "funnels" the noise into the ear canal which acts as a resonating chamber increasing the sound level pressure, particularly at the 4000 Hz frequency range.

- Middle Ear: The middle ear begins at the ear drum (tympanic membrane) and includes three small bones called the ossicular chain (i.e., the hammer-malleus, anvil-incus, and stirrup-stapes). The ossicular chain incorporates two movable parts, the round and oval windows. On either side of the bony structure is the opening to the eustachian tube and the mastoid air cells. This portion of the ear translates the sound pressure from the ear canal into the inner ear where the noise is perceived.

- Inner Ear: The inner ear, filled with endolymph fluid, includes the vestibular receptive system (responsible for position) and the cochlea (responsible for hearing). The vestibular system allows for balance. The cochlea contains feather-like hair cells that vibrate (from sound pressure) at different frequencies and nerve endings within an interior complex structure called the organ of corti. Hearing is perceived and communicated to the brain in this area of the ear.

Conductive Hearing Loss

Hearing loss involving the outer or middle portions of the ear is termed conductive hearing loss. This type of hearing loss can be caused by fixation of the bones in the middle ear that prohibits their movement or interruption of the bone chain. Most conductive hearing loss occurs as a result of infection or head trauma. With conductive hearing loss the loudness of the sound is reduced due to the reduced ability of the middle ear to conduct the sound to the inner ear though the clarity is preserved because the cochlea in the inner ear is preserved.

Sensorineural Hearing Loss

Hearing loss involving the inner portion of the ear is termed sensorineural hearing loss. Sensorineural hearing loss can involve impairment of the cochlea and/or the nerves. Both loudness and clarity are affected by sensorineural hearing loss. Damage to the feather-like hair cells and/or the nerves are caused by repeated trauma to these organs when high levels of noise is encountered over a period of time. Sensorineural hearing loss is the most common in occupational and recreational settings with exposures to hazardous noise of a period of months or years. This type of hearing loss is not reversible.

For more information, see Plog & Quinlan, Fundamentals of Industrial Hygiene, 6th Edition.

MSHA Noise Regulation

In 1999, MSHA published new health standards for Occupational Noise Exposure. The revised noise rule took effect on September 13, 2000 in the form of 30 CFR Part 62. Prior legislation had not been updated for 20 years. The following key requirements were established within the noise rule.

- Requires mine operators to use all feasible engineering and administrative controls to reduce miners' noise exposure to the "permissible exposure level" (PEL). Hearing protectors are not permitted in lieu of such controls. The PEL is defined as 90 dBA measured as an 8-hour time-weighted average (TWA8). Establishes an action level at 50% of the PEL, at which miners must be enrolled in a hearing conservation program (HCP). The action level is defined as 85 dBA measured as TWA8.

- The HCP includes provisions for assessing miners' noise exposure; audiometric (hearing) tests; hearing protectors; training; and recordkeeping.

- Mine operators must also ensure that no miner is exposed at any time to sound levels exceeding 115 dBA.

The following table, adopted from the MSHA Noise Regulation Fact Sheet, details the requirements of the mine operator with respect to measured exposure levels defining a miner's noise exposure.

| If a miner's noise exposure is... | Then a mine operator is required to... |

| Below the action level | No requirements |

| Equals or exceeds the action level but does not exceed the PEL | Enroll the miner in a hearing conservation program (HCP). Provide hearing protectors to the miner. Ensure that the hearing protectors are worn if the miner has a standard threshold shift or it will be longer than 6 months before receiving a baseline audiogram. |

| Exceeds the PEL | Use all feasible engineering and administrative controls to reduce miner's noise exposure to the PEL. Enroll the miner in an HCP. Provide hearing protectors and ensure they are worn, if unable to reduce exposure to the PEL. |

| Exceeds 105 dBA TWA8 (dual hearing protection level) | Same as exceeds the PEL, plus provide the miner with both ear plug and ear muff type hearing protectors and ensure they are worn concurrently. |

| Instantaneous measurements of noise exceed 115 dBA | No miners, including those with dual hearing protectors, are permitted to be exposed to sound levels exceeding 115 dBA. |

Additional information on noise standards may be found at the Mine Safety and Health Administration website.

Instantaneous Noise Survey

Instantaneous Noise Survey and Octave Band Analysis

Field measurements must be taken in order to know how loud a piece of equipment operates or an individual's personal exposure to noise throughout a work shift. Several types of noise surveys are involved in a comprehensive noise program: an instantaneous noise survey, octave band analysis, noise dosimetry, and a time-motion study. This section of instruction will cover instantaneous noise measurements and introduce octave band analysis. The following modules will discuss noise dosimetry and time-motion surveys, respectively.

Instantaneous Noise Survey

An instantaneous noise survey is used to document the operating noise levels for each piece of equipment. This helps a mine operator define any equipment that exceeds 115 dBA (a level to which no miner shall be exposed for any period of time per MSHA) as well as identifying equipment that might result in more exposure than others (i.e., equipment to which even "passers by" would need to wear hearing protection in the "hazardous noise area").

An instantaneous noise survey can also be used to prioritize work areas for evaluation. If area measurements while operations are ongoing produce dBA noise levels at or below 80 dBA, the area can be prioritized later for evaluation. Areas where area noise measurements exceed 80 dBA and above may be prioritized earlier in the baseline evaluation process.

This survey is conducted with an instantaneous sound level meter (pictured on the right). There are many manufacturers of noise meters. The meter you purchase or rent should be a Type II Sound Level Meter set to the following parameters.

- "Slow" response

- dBA setting

- Range of 80 - 120 dBA

The instruments should be field calibrated prior to and after use to ensure accuracy (within +/- 0.3 dB). It is also important to take the noise measurements at the operator position (i.e., the location(s) where the operator, assistant, or other worker is or would be positioned during use) while the equipment is under load (i.e., actual use with materials or substrates). Equipment is much louder and operates at different frequencies while under loaded conditions.

Octave Band Analysis

An octave band analysis is used to define the primary frequency or frequencies in which the equipment is operating. This measurement, while not required during routine noise monitoring, is essential when considering noise control options. This measurement is more involved and will only be covered in an introductory fashion in this training format. Many sound level meters have incorporated octave band analyzers that will provide a noise measurement at a variety of frequencies, called center frequencies, in Hertz (e.g., 37.5, 63, 125, 250, 500, 1K, 2K, 4K, 8K). When noise measurements are collected with the filters "on" to limit noise to certain frequency ranges, the predominant frequency/frequencies will be represented by the highest noise levels. Many older meters require measurements collected in a "linear" mode in which a mathematical weighting must be applied by the user to determine the equivalent dBA measurement. Most newer octave band analyzers will provide the weighted, corrected value. You will need to check the noise instrument manual if completing these measurements to determine if a mathematical weighting adjustment needs to be completed following the measurements.

Noise Dosimetry

Noise dosimetry is used to provide a measurement of average noise levels over the period of a work shift (usually 8-hours). A noise dosimeter is similar to a noise meter; however, the noise dosimeter will average the measurements to provide a TWA8 and dose% equivalent for direct comparison with MSHA standards.

The dosimeter (pictured on the right) must be set to the following parameters prior to collecting measurements for MSHA compliance.

- Exchange Rate - 5 dB

- Threshold - 80 dBA

- Criterion Level - 90 dBA

Resources

Download the Noise Dosimetry Field Data Form (PDF) for an example form that can be used in the field by the technician.

Time-Motion/Work Study

A useful tool in the evaluation of personal noise exposure is a "time-motion study". A time-motion study involves logging significant tasks and equipment used and their length of use during the course of a noise dosimetry study. This will allow for the correlation of high periods of noise exposure to the tasks or process that produce the most noise exposure. One can then prioritize equipment and/or tasks for incorporation of engineering or administrative controls.

The time-motion study complements the noise dosimetry field data form (available at the noise dosimetry module) and printable time history data printed from the noise dosimeters. When reviewing printable time histories from the noise dosimeters, it is helpful to know what tasks were being completed during peak noise periods within the work shift.

Resources

The following form may be used to document field notes either from the industrial hygienist/safety professional or the work place supervisor and employee. Download the Time-Motion Study Data Form.

Data Interpretation

Once the field data has been collected from the instantaneous noise survey, octave band analysis (if completed), noise dosimetry, and time-motion study, it is time to piece the information together to obtain a picture of the noisy environment and how these measurements compare to MSHA standards.

Instantaneous Noise Survey

This data provides information as to which equipment and areas exceed 115 dBA. Immediate action is required in areas or with equipment exceeding 115 dBA. Immediate noise controls need to be implemented as MSHA standards do not allow for exposure to personnel at this level for any period of time. If controls are not possible or feasible, a variance needs to be filed with MSHA and steps need to be taken for redesign of the area/equipment.

The instantaneous noise survey will also allow for the industrial hygienist/safety professional to establish hazardous noise areas (delineated by signage and often by painted lines on the concrete flooring) to visually identify areas in which any personnel (even passers by) must wear hearing protection. The hazardous noise areas should be established for equipment/areas with noise levels of 85 dBA sustained (i.e., when the equipment is in operation).

Octave Band Analysis

While not required for routine noise monitoring, these measurements are essential for the definition of noise sources in terms of operating frequency or spectrum and for design of noise controls. Equipment operating at noise frequencies of 500 Hz and higher (500 Hz - 16,000 Hz) are believed to have an increased effect on personal hearing loss compared to equipment operating at lower frequencies. Further, certain noise controls are efficient for high or low frequencies, respectively.

Noise dosimetry

TWA8 and % Dose measurements collected from noise dosimetry are compared directly to the MSHA permissible exposure limit of 90 dBA TWA8 (i.e., 100% dose) and the action level 85 dBA TWA8 (i.e., 50% dose). These measurements are the basis for MSHA compliance and dictate the mine operator's responsibilities under the regulation.

Time-Motion Study

This study, while not required by MSHA is certainly helpful to discern what tasks, processes, and equipment contribute the most to the personal exposure. It allows industrial hygienists and safety professional to provide recommendations on which processes and which equipment should be evaluated for noise controls or administrative controls with respect to measured results.

Noise Controls (Engineering, Administrative, PPE)

The current MSHA regulation dictates the use of engineering and administrative controls to reduce exposures to hazardous noise levels. This module will provide a basic introduction into various controls as well as provide information regarding personal protective equipment for noise.

Engineering Controls

The following types of engineering controls can provide varied decibel reduction when applied to the correct equipment and in the proper manner: Equipment substitution, changing equipment operating conditions (i.e., reduce velocity, reduce driving force, etc.), equipment noise enclosures, personnel noise enclosures, shields/barriers, sound absorption, vibration dampening materials, lagging, and mufflers. The feasibility of the controls should be considered when designing noise engineering controls.

Administrative Controls

The following types of administrative controls can provide varied decibel reduction when consistently applied: limiting worker time in the noise area or operation and procedures for equipment operation that reduces noise levels (e.g., control of compresses air pressure and electrical current settings during air-arc gouging).

Personal Protective Equipment

While hearing protection is not to be used in lieu of engineering or administrative controls the use of hearing protection is widespread and usually long-term. It is important to ensure personnel who are required to wear hearing protection do so consistently and correctly. A variety of studies have shown that the noise-reduction rating on the hearing protection is seldom attained by workers who are not adequately trained on how to insert and use hearing protection. Fit-testing devices are now available to allow the user to see the type of fit they are receiving with the ear plugs they are using. This tool has been shown to dramatically increase correct hearing protector application and reduce noise exposure.